ماكينة formation end mill

Multi-Flute End Mills Produce Thoroughly Modern Milling

网页2021年1月26日 The cutting edge in this Iscar end mill is designed to help split chips. The DOC can also be increased. For example, the machinist

[خذ المزيد]

End Mills McMaster-Carr

网页When one end wears out, switch to the opposite end for two times the life of a standard carbide end mill. Made of solid carbide, these end mills are harder, stronger, and more

[خذ المزيد]

End Milling Process Different Types of End Mills

网页2022年11月4日 End milling involves using a specific cutting tool, an end mill, to make axial cuts into a workpiece. It is an aspect of milling operation used for special applications such as producing die cavities, profiles,

[خذ المزيد]

Guide: How to select the best CNC end mill? - Mekanika

网页2022年11月21日 Ball end mills have rounded tips and are used to mill 3D shapes or rounded grooves. T-slot end mills can easily cut accurate keyways and T-slots to create

[خذ المزيد]

Basic End Mills Technical Information MSC Industrial

网页高达1.6%返现 Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting

[خذ المزيد]

HP End Mills - Melin Tool Company

网页Recently expanded Melin Micro End Mill line. Melin now offers several existing Carbide End Mill series in Micro sizes as well as new micro products series. Our latest Micro expansions offers the following

[خذ المزيد]

Tube End Forming Machines - Tube End Formers Tube

网页Tube End Formers. Tube end forming machines can produce a variety of end forms for various functions. End Forming (also called End Finishing) is the type of process that

[خذ المزيد]

ماكينة formation end mill - culinairetop50.online

网页ماكينة formation end mill. ... mills Indexible insert milling Forming taps Thread cutting Success Stories Downloads amp Contact With our solid carbide end mills from the DHC

[خذ المزيد]

ماكينة formation end mill

网页Tradução Inglês do Run . A run made side to side as opposed to end to end or diagonally This term may also be applied to a transit of any formation of sweepers in action or

[خذ المزيد]

ماكينة formation end mill

网页and titanium. Not for use on aluminum. Color is purple-gray. The choice to use coated end mills is a cost versus benefit choice.ماكينة تشكيل الالمينيوم. ماكينة تشكيل الباب المنزلق. ماكينة formation

[خذ المزيد]

Ball End Mills - Haas Automation

网页HTPM series milling cutters have unequal flute spacing (variable pitch) and multiple helix angles (35° and 37°) to reduce chatter and harmonics, for improved stability and better finishing. This also optimizes chip formation and chip evacuation. These 4-flute end mills feature a spherical ball end. Aluminum Chromium Nitride (Hybrid AlCrN) coating reduces

[خذ المزيد]

CBN end mill series

网页radius end mill The realization of excellent performance when milling hardened steel over 65HRC. CBN end mill series, the ultimate choice for finish machining of molds. Feature 1 An original manufacturing method allows Feature 2 a wide variety of neck lengths Cutting edge geometry that offers excellent chip disposal enables long, stable operations.

[خذ المزيد]

End Milling Process Different Types of End Mills - WayKen

网页2022年11月4日 End milling involves using a specific cutting tool, an end mill, to make axial cuts into a workpiece. It is an aspect of milling operation used for special applications such as producing die cavities, profiles, slots, contours, shoulders, and other milling parts.

[خذ المزيد]

Multi-Flute End Mills Produce Thoroughly Modern Milling - SME

网页2021年1月26日 The cutting edge in this Iscar end mill is designed to help split chips. The DOC can also be increased. For example, the machinist could run a process using a 5/8" (1.6-cm) diameter, two-flute end mill on titanium 6AL-4V at 130 sfm using full slotting and 1× the diameter DOC for productivity of 1.49 in³/min. (24.4 cm3/min.).

[خذ المزيد]

CNC End Mill Comparison Guide MatterHackers

网页2020年2月18日 Coatings. End mills are made of a few different materials, but “high-speed steel” (HSS) and tungsten carbide are two of the most common. The HSS tools are more forgiving than carbide, as carbide is brittle and can chatter and shatter. HSS is also cheaper than carbide, but it tends to dull faster than carbide.

[خذ المزيد]

End Mills McMaster-Carr

网页When one end wears out, switch to the opposite end for two times the life of a standard carbide end mill. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Use them to round sharp corners on the edge of your workpiece.

[خذ المزيد]

How to Optimize Results While Machining With Miniature End Mills

网页2020年7月1日 In theory, doubling the length sticking out of the holder will result in 8 times more deflection. Doubling the diameter of an end mill it will result in 16 times less deflection. If a miniature cutting tool breaks on the first pass, it is most likely due to the deflection force overcoming the strength of the carbide.

[خذ المزيد]

Guide: How to select the best CNC end mill? - Mekanika

网页2022年11月21日 Ball end mills have rounded tips and are used to mill 3D shapes or rounded grooves. T-slot end mills can easily cut accurate keyways and T-slots to create working tables or other similar applications. Straight flutesend mills have a zero degrees helix. They work well for materials where the lifting effect of a spiral flute might cause

[خذ المزيد]

ماكينة formation end mill

网页and titanium. Not for use on aluminum. Color is purple-gray. The choice to use coated end mills is a cost versus benefit choice.ماكينة تشكيل الالمينيوم. ماكينة تشكيل الباب المنزلق. ماكينة formation end mill ماكينة formation end mill Wire Cutting Machin Feb 16, اقرأ أكثر

[خذ المزيد]

ماكينة formation end mill

网页2021年5月31日 PDF Geometric Modeling of End Mills - يتعلم أكثر. Tandon et al 3 4 5 have proposed the unified modeling schemes for side milling cutters end mills slab mills and fluted cutters The work in the direction of geometry design of a form . JET 650210 20 Piece Tin Coated Double End Mill Set - يتعلم أكثر

[خذ المزيد]

Tech Tip: Coatings for Solid Carbide End Mills - Kennametal

网页Titanium Nitride (TiN) coatings are used for general-purpose milling operations in softer materials. The coating offers high surface lubricity, reduces friction, and increases chip flow. The resistance in heat and hardness allows the tool to run about 20-30% higher machining speeds than uncoated end mills.

[خذ المزيد]

what is an end mill and how to make an end mill - Huana Tools

网页2022年5月25日 Chamfer End Mill : By creating a cutting action, most materials can be chipped more easily. With chamfering, feed rates can be higher, as well as efficiency increases. Using their angled profile, aluminum, brass, bronze, iron, and steel can be chamfered, beveled, or otherwise shaped. Square End Mill:

[خذ المزيد]

OPTIMIZED ROUGHING A Complex Process Made Simple-end mill

网页2020年4月1日 End mill diameter should measure half the cutting length/ depth of cut; beyond that point, axial cutting pressures cause end mill deflection and hamper good chip formation. Deep axial cuts require the use of chipbreakers, notched cutting edges that prevent chips from wrapping around end mills or part features and causing damage to

[خذ المزيد]

The Anatomy of an End Mill - In The Loupe - Harvey

网页2017年12月10日 End Mill Helix Angle The helix angle of a tool is measured by the angle formed between the centerline of the tool and a straight line tangent along the cutting edge. A higher helix angle used for finishing (45°, for example) wraps around the tool faster and makes for a more aggressive cut.

[خذ المزيد]

CBN end mill series

网页radius end mill The realization of excellent performance when milling hardened steel over 65HRC. CBN end mill series, the ultimate choice for finish machining of molds. Feature 1 An original manufacturing method allows Feature 2 a wide variety of neck lengths Cutting edge geometry that offers excellent chip disposal enables long, stable operations.

[خذ المزيد]

Guide: How to select the best CNC end mill? - Mekanika

网页2022年11月21日 Roughing end mills are used to quickly remove large amounts of material during heavy operations. Their design allows for little to no vibration but leaves a rougher finish. Tapered end mills are centre-cutting tools that can be used for plunging, and are designed to machine angled slots. They are generally used in die-casts and moulds.

[خذ المزيد]

Ceramic End Mill Achieves Long Life and High MRR at Standard

网页2021年6月4日 Now, ceramic cutting tool maker Greenleaf says innovations in the toughness of ceramics within the last five years offer the potential to dramatically expand the applicability of ceramic tools in milling. The company recently launched its “Xsytin 360” line of solid-body four-flute ceramic end mills, after two years of development.

[خذ المزيد]

Tech Tip: Coatings for Solid Carbide End Mills - Kennametal

网页Titanium Nitride (TiN) coatings are used for general-purpose milling operations in softer materials. The coating offers high surface lubricity, reduces friction, and increases chip flow. The resistance in heat and hardness allows the tool to run about 20-30% higher machining speeds than uncoated end mills.

[خذ المزيد]

How to Optimize Results While Machining With Miniature End Mills

网页2020年7月1日 In theory, doubling the length sticking out of the holder will result in 8 times more deflection. Doubling the diameter of an end mill it will result in 16 times less deflection. If a miniature cutting tool breaks on the first pass, it is most likely due to the deflection force overcoming the strength of the carbide.

[خذ المزيد]

what is an end mill and how to make an end mill - Huana Tools

网页2022年5月25日 Chamfer End Mill : By creating a cutting action, most materials can be chipped more easily. With chamfering, feed rates can be higher, as well as efficiency increases. Using their angled profile, aluminum, brass, bronze, iron, and steel can be chamfered, beveled, or otherwise shaped. Square End Mill:

[خذ المزيد]

Indexable End Mills from HaasTooling - Haas Automation, Inc.

网页ماكينات التفريز العمودية ; سلسلة vf; الماكينات الموحدة; سلسلة vr; مراكز الماكينات العمودية لتغيير المنصات

[خذ المزيد]

ماكينة Formation End Mill - Hpfeiffer

网页ماكينة Formation End Mill. ما هو ال ball mill. Chip formation in most all end mills on the market have used the horsepower and torque of the machine spindle to force the material being machined into 6 9 shaped chips The shapes are the look of the curled once the tool has forced the material to separate from itself .

[خذ المزيد]

ماكينة formation end mill - Broodenbanketfre

网页ما هو ال ball mill. Chip formation in most all end mills on the market have used the horsepower and torque of the machine spindle to force the material being machined into 6 9 shaped chips The shapes are the look of the curled once the tool has forced the material to separate from itself

[خذ المزيد]

Ball-Nose End Mills McMaster-Carr

网页Cobalt Steel Ball End Mills with Two Milling Ends. With better heat and wear resistance than high-speed steel, these cobalt steel end mills can run at higher speeds and provide better performance on hard material, such as iron, hardened steel, titanium, and tool steel. When one end wears out, turn the tool around for a sharp edge.

[خذ المزيد]

OPTIMIZED ROUGHING A Complex Process Made Simple-end mill

网页2020年4月1日 End mill diameter should measure half the cutting length/ depth of cut; beyond that point, axial cutting pressures cause end mill deflection and hamper good chip formation. Deep axial cuts require the use of chipbreakers, notched cutting edges that prevent chips from wrapping around end mills or part features and causing damage to

[خذ المزيد]

Multi-Flute End Mills Produce Thoroughly Modern Milling - SME

网页2021年1月26日 End mills, traditionally made with two to four flutes, are used in one of the oldest mechanized machining processes—milling. Cutting-edge software, machine tools, novel strategies, ever-improving techniques and design updates in the tools themselves keeps milling useful in the 21st century.

[خذ المزيد]

End Mills McMaster-Carr

网页When one end wears out, switch to the opposite end for two times the life of a standard carbide end mill. Made of solid carbide, these end mills are harder, stronger, and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard material. Use them to round sharp corners on the edge of your workpiece.

[خذ المزيد]

Influence of End Mill Geometry on Milling Force and Surface

网页2020年9月4日 In the end milling process, the roughness of the surface is due to the tooth marks (lay marks) left when machining the surface. These tooth marks are affected by different factors such as tool geometry, workpiece material, and cutting conditions.

[خذ المزيد]- معلومات عن تكسير الحجارة

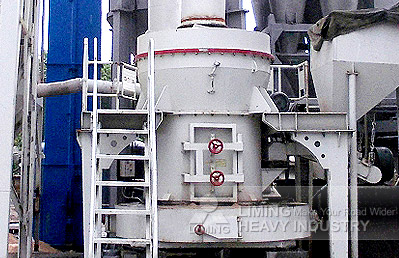

- مطحنة جبس ريمون مطحنة

- كسارات مخروط للبيع كوستاريكا

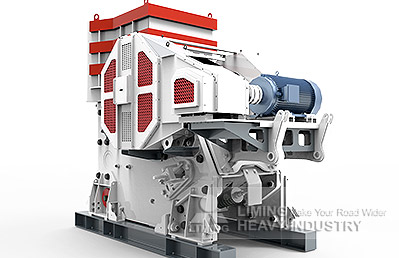

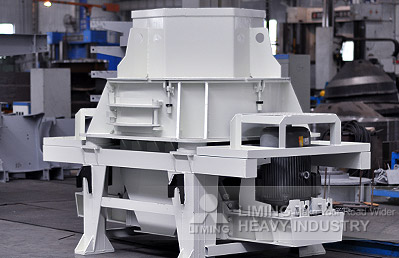

- كسارة صدم كسارة متحركة

- المستخدمة الصين محطم

- الأكثر ملاءمة المعدنية كسارة

- تستخدم معدات جواهري جنوب أفريقيا

- لفة التصميم التفصيلي محطم

- حفر النار كسارة المخاريط للبيع في ألبرتا

- محطم في sabadell بيع

- الفك كسارة الصخور البورصة سلسلة

- المورد الحجر الجيري في ليمبوبو ليمبوبو

- كسارة صخور ألمانيا

- صور ماكنة قص حديد صاج رول

- آلات طحن الرقصة المستخدمة في سويسرا

- تهتز الشاشة من الفحم

- هیچ پاره پاره کننده

- مصنعي آلات صناعة الرمل المسحوق في ألمانيا

- لي حجر كسارة الفك محطم

- كسارة مخروط دلو ref12004279

- بيلو هوريزونتي الشاشة تهتز

- ناقلات الحركة

- مجموعة سلسلة شركات المروة للمعدات الثقيلة ببنها

- محجر كسارة الحجر شكل المؤسسة الوطنية للنفط ولاية راجاستان

- التعدين الكوارتز معدات تنزانيا محطم مبيعات للبيع

- إعصار التعدين معدات خام الحديد

- معدات التعدين مسحوق البنتونيت

© Copyright - PETER&X محطم