Ball Race Mill Coal

Raymond® Ball Race Mills - Schenck Process

High availability a) As there are no bearings in the coal flow path, there’s no need for period inspection of journals. b) Handles a range of fineness from 70% passing 75 microns (200

[خذ المزيد]

Analyses of the energy-size reduction of mixtures of

2018年6月1日 Breakage process of mixture in ball mill is different with that in ball-and-race mill due to difference in grinding mechanism. Methods proposed for energy split study of

[خذ المزيد]

An analysis of the energy split for grinding coal/calcite

2016年7月1日 In this paper, energy split phenomenon for the coarse grinding of super clean anthracite coal (SCAC)/calcite mixture of 2.8–2 mm in the ball-and-race mill is

[خذ المزيد]

Effect of particle properties on the energy-size reduction of coal

2018年6月15日 It was found that the ball mill consumed 54.67 kWh/t energy to reduce the F 80 feed size of 722.2 µm to P 80 product size of 275.4 µm while stirred mill consumed

[خذ المزيد]

Minerals Free Full-Text Grinding Behaviors of

2020年3月3日 Abstract. Coals used for power plants normally have different ash contents, and the breakage of coals by the ball-and-race mill or roller mill is an energy-intensive process. Grinding phenomena in mill of

[خذ المزيد]

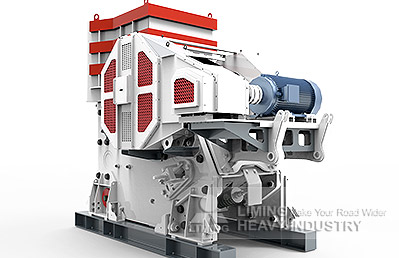

Coke and coal grinding in a ball race mill. Operational features

2001年5月3日 Coke and coal grinding in a ball race mill. Operational features Abstract: This paper gives a general description of the modern ball race mill, describes how shot

[خذ المزيد]

Causes of pulverized-coal leakage from a race pulverizer and

2007年3月1日 Request PDF Causes of pulverized-coal leakage from a race pulverizer and its seal system modification A pulverized coal preparation system is one of the

[خذ المزيد]

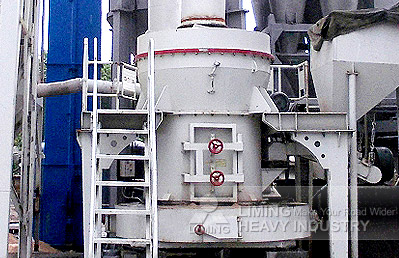

Coal Pulverizer – Power Plant Pall Corporation

3 天之前 Ring-Roll and Ball-Race Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs. One or both of the races may rotate

[خذ المزيد]

Pulveriser in Thermal Power Plant Bowl Mill Ball Mill

5 天之前 Types Of Coal Pulveriser. Slow speed mills like ball mill; Medium speed mills like bowl mill; High speed impact mill; The slow speed and medium speed mills are selected

[خذ المزيد]

Effect of particle properties on the energy-size reduction of coal

2018年6月15日 It was found that the ball mill consumed 54.67 kWh/t energy to reduce the F 80 feed size of 722.2 µm to P 80 product size of 275.4 µm while stirred mill consumed 32.45 kWh/t of energy to produce the product size of 235.6 µm. It also showed that stirred mill produced finer product than the ball mill at around 40% lesser consumption of energy.

[خذ المزيد]

Modelling of vertical spindle mills. Part 2: Integrated models

2015年3月1日 The main difference is that the ball-race design uses steel balls whilst the roller-race design uses rollers. This does not affect the structure of the models but the different pulveriser designs require slightly different calculations. As discussed in Part 1 of the paper, a VSM operation consists of three basic. E-mill (ball-race) model

[خذ المزيد]

Effect of particle properties on the energy-size reduction of coal

2018年6月15日 Vertical roller mill (VRM) is widely used in coal power plants to prepare PF, and flow direction of coal in VRM is shown in Fig. 1. Particle breakage and classification happens in closed phenomenon. ... Grinding behavior of coal blends in a standard ball-and-race mill. Energy Fuel, 9 (1995), pp. 59-66. CrossRef View in Scopus Google Scholar [19]

[خذ المزيد]

Analyses of the energy-size reduction of mixtures of

2018年6月1日 Energy-size reduction experiments of particles in narrow and wide size were conducted in a modified ball-and-race mill, namely Hardgrove mill, with the addition of a power meter. Materials were SCC particles in size of 2.8–2 mm, 2–1.25 mm and 1.25–0.71 mm. SCC particles in neighboring size were mixed with mass ratios (coarse-to-fine) of 3 ...

[خذ المزيد]

A new model-based approach for power plant Tube-ball mill

2014年4月1日 Tube-ball mill is another dominant type of coal mill apart from Vertical Spindle mill in industry. Compared with the Vertical Spindle mills, Tube-ball mills have a much higher grinding capacity. ... An analysis of ball-and-race milling, Part II: the Babcock E-1.7 Mill. Powder Technol, 33 (1982), pp. 113-125. View PDF View article View in Scopus ...

[خذ المزيد]

Coal mill pulverizer in thermal power plants PPT - SlideShare

2012年11月17日 20. 13.1.Fineness Fineness is an indicator of the quality of the pulverizer action. Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance. The mill

[خذ المزيد]

Grinding Behavior of Coal Blends in a Standard Ball-and-Race Mill

Enter the email address you signed up with and we'll email you a reset link.

[خذ المزيد]

Effect of particle properties on the energy-size reduction of coal

DOI: 10.1016/J.POWTEC.2018.04.018 Corpus ID: 103058724; Effect of particle properties on the energy-size reduction of coal in the ball-and-race mill @article{Xie2018EffectOP, title={Effect of particle properties on the energy-size reduction of coal in the ball-and-race mill}, author={Weining Xie and Yaqun He and Lili Qu and Xiaolu Sun and Xiang-nan

[خذ المزيد]

Coal Pulverizer – Power Plant Pall Corporation

2 天之前 Ring-Roll (Bowl-Mill) and Ball-Race Mills comprise most coal pulverizers currently in service at pulverized coal power plants. The grinding rolls are stationary in this design, while a worm gear drive rotates the ring (commonly known as the bowl). Powerful springs force the grinding rolls against the ring, providing the pressure required to ...

[خذ المزيد]

Pulverizer Plant OM Aspects

2013年12月6日 Tube and ball mill Bowl Mill, Ball and Race mill Beater Mill, Impact Mill . 13 BOWL MILL Model no. Base capacity(T/Hr) 623XRP 18.4 703XRP 26.4 ... Maximum mill Capacity vs coal moisture at coal HGI 100-110 and PF Fineness of 70 % passing through 200 Mesh 35.00 36.00 37.00 38.00 39.00 40.00

[خذ المزيد]

Causes of pulverized-coal leakage from a race pulverizer and

2007年3月1日 Coke and coal grinding in a ball race mill. Operational features. February 2001. C. Schossow; This paper gives a general description of the modern ball race mill, describes how shot coke is ground ...

[خذ المزيد]

A multi-component model for the vertical spindle mill

2016年3月10日 Effect of particle properties on the energy-size reduction of coal in the ball-and-race mill. 2018, Powder Technology. Citation Excerpt : Improvement of grinding efficiency and reducing energy consumption should base on a good understanding of energy-size reduction process. Though coal power plants make great contributions to

[خذ المزيد]

An analysis of ball-and-race milling. Part I. The hardgrove mill

1981年7月1日 In order to express the filling of the mill on a rational basis, the empty volume of the ball-race system was calibrated using known volumes of water, with the result shown in Fig. 5_ The volume to fill the race to the top of the balls was taken as 10090 filling, and the fractional filling f, defined 3s _ (mass powder, g)/p B f` 125 cm a where ...

[خذ المزيد]

Grinding Behavior of Coal Blends in a Standard Ball-and-Race Mill

Revised Manuscript Received November 1, 1994@ An investigation was carried out to predict the size-composition make-up of the product of a coal blend ground in a ball-and-race mill using the breakage characteristics of the individual components determined by separate grinding.

[خذ المزيد]

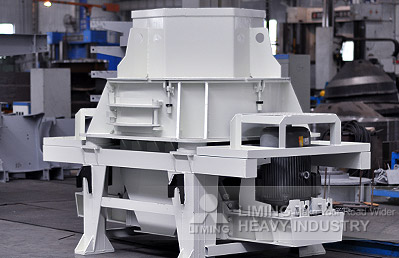

Roller mills - INFINITY FOR CEMENT EQUIPMENT

Ball race mill (Peters-mill of the Claudius Peters Joint Stock Company, Hamburg, Germany). The cement industry employs the Peters-mill (pre viously called Fuller-Peters-mill) mostly for coal grinding. It is a few years now that the shockproof construction (shock resistance – 3.5 bar) of the Peters-mill was designed for coal grinding.

[خذ المزيد]

Derivation and validation of a coal mill model for control

2012年5月1日 Coal mill models can trace their roots back to the early 1940s where several groups of researchers worked on the mathematical modeling of mills and the development of grinding theory. ... 1982a, Austin et al., 1982b in their series of papers analyze a ball-and-race mill. In the study they derive a detailed model based on a scale-up of the ...

[خذ المزيد]

Ball mill - Raymond® - Schenck Process Holding GmbH

Grinding elements of ball race mill consists of one set of top and bottom ring and a number of large diameter hollow balls. a) Balls are free to rotate about both axis. Balls wear uniformly and retain its spherical shape throughout its life. b) Product fineness remains same throughout the life. • Fineness adjustment is done by changing the ...

[خذ المزيد]

Energy Engineering Questions and Answers – Pulverised Mills

2024年2月18日 Explanation: The pulverization or crushing action in ball and race mill takes between the two moving surfaces called balls and races. The rolling action happens between these two. Then the coal passes between the rotating elements time and again until it has been pulverized to the desired degree of fineness.

[خذ المزيد]

Maintenance Practices for Ball and Race Mills at

2018年11月6日 Ball and Race Mill - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. 1. The document discusses maintenance practices for a ball and race mill used in a coal-fired power plant. 2. It describes preventative, predictive, proactive, and planned maintenance approaches used to maximize availability and

[خذ المزيد]- ASM المتداول مطحنة في نيجيريا

- موضوع خاص للكراء المعدات البناء

- مطاحن مطرقة محلية ثانية للبيع

- موردي خطة التكسير Tsouth Africa

- باکستر قطعات سنگ شکن فکی

- الكرة مطحنة تركيا للبيع

- مستعمل كسارة حجر الفك

- بودرة التلك الطائرات

- تيتان كسارة الحجر

- كسارة دوارة إندونيسيا

- طحن مصغرة رمح المحمولة

- متطلبات محطة تكسير الصابورة

- مناجم الحجر الجيري في بانكورا

- سنگ شکن در اوج سنگ

- بناء الموردين الرمل غوتنغ التعدين

- كسارة الفك المحمول للبيع في النمسا

- التوابل طاحونة التجارية

- الصين الصناعة الثقيلة

- محطات سحق المحمول عبر الهند 200tph

- گرد و غبار سنگ زنی بتن

- تحميل نموذج محطم التعدين

- متوسطة السرعة مطحنة فاصل الخلفي من هيكل

- ما هو النقص في الطحن

- مناجم الصين في شنغهاي

- تأجير نباتات التكسير في الجزائر

- كندا معهد التعدين والمعادن المؤتمر السنوي الواحد والثمانين

- قائمة أصحاب محاجر المعدن الأزرق في ولاية كارناتاكا

- مخروط محطم الصانع في كوريا

- مصنع محطم في جنوب السودان

- طحن الاسمنت مطحنة التهوية

© Copyright - PETER&X محطم